|

|

|

STEELE CREEK NEWS

Why Do We Have So

Much

Industry? It All Started with the Shell Plant

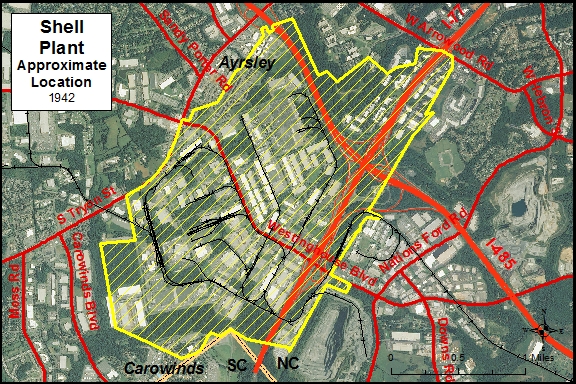

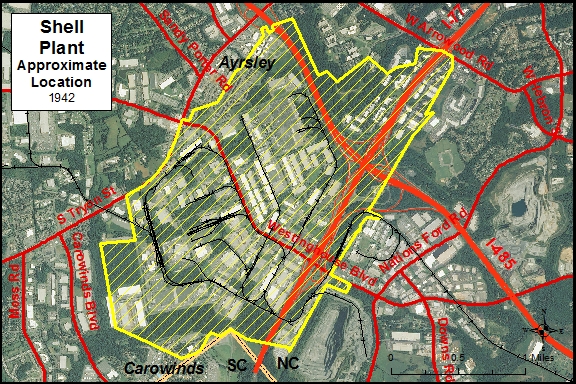

(December 28, 2015) The Westinghouse Industrial Corridor is reportedly the

second largest employment center in Mecklenburg County behind Uptown

Charlotte and the largest industrial employment concentration in the state of

North Carolina.

The corridor is the dominant

feature affecting the geography of Steele Creek. It carves a

large nonresidential swath through the middle of our

community, separating

Ayrsley, Berewick, Taragate, and other neighborhoods to the

north from the Crossings, the Palisades, the Sanctuary,

Yorkshire, and other neighborhoods around the RiverGate

corner to the south. It provides employment for many Steele

Creek residents but also generates a huge amount of traffic from

employees driving into Steele Creek and clogging I-485 inbound

in the morning and outbound in the afternoon. A large

network of railroad spurs totaling about 30 miles continues

to serve industries in Steele Creek today. |

|

Bofors 40 mm anti-aircraft guns on a Mk 12

quadruple mount firing on board

USS Hornet (CV-12), circa February 1945,

probably during gunnery practice. |

It all got started in

1942 when a facility known locally as the Shell Plant was built to produce ordinance to

support the Navy effort during World War II. The old Shell Plant

covered 2260 acres. The land was sold by the federal government in

1959, after the plant closed. It became the Arrowood Business Park

and was subdivided and sold off in smaller parcels. Later it spawned

additional industrial development along Westinghouse Boulevard both

east and west of the old Shell Plant as well as along Carowinds Blvd. The map below shows the area of the Shell Plant

in yellow cross hatch based on a variety of historic maps.

The following was adapted from an article by

Walter Neely in Gleanings, Newsletter of the Steele Creek

Historical and Genealogical Society.

History of the Shell Plant – Part 1

The Charlotte Observer published an article

about the Shell Plant on June 9, 1942, only three days after deed transfers for the first properties were

registered.

The article said that

surveyors had taken the first physical step toward construction of

the huge plant. It would be operated by the United States Rubber

Company for the production of ammunition for the United States Navy.

The article said that there would be about 3,000 persons on

average employed in building the plant. It said that prospective

workers should report to the site of the plant and make applications

there in about a week. They predicted that construction might

require six months.

In the meantime several officials of the

United Sates Rubber Company had come to Charlotte from New York to

help prepare for operation of the immense ordinance plant. Once the

plant began operations, it was expected employ approximately 6,000

persons, the article stated.

It is unclear why the United States Rubber Company, later Uniroyal,

obtained this contract since they primarily produced tires and

rubber products. The entire contract worth $9,000,000.00 can be

found in Book 1132 page 365 of the Mecklenburg Register of Deeds.

Its title page states that it is a “Contract for the Acquisition and

Installation of Special Additional Plant Equipment and Facilities

Required to Expedite the National War Effort. Increase and

Replacement of Naval Vessels Amor, Armaments, and Ammunition.” The

contract, dated June 1, 1942, was between the United States of

America and United States Rubber Company and signed by W. H. P.

Blandy, Chief of the Bureau of Ordinance, acting under the Authority

of the Secretary of the Navy.

The Scope of the Contract was

for the contractor to “acquire and install or construct the

buildings, machinery, equipment, facilities, services and

appurtenances identified….furnishing or causing to be furnished the

labor, materials, tools, machinery, equipment, facilities, supplies

and services, adequate first aid, guard and fire fighting forces,

and doing or causing to be done all other things necessary for the

acquisition, installation, and construction thereof.” The contract

and expenditures were authorized by Public Law No. 354, 77th

Congress (December 18, 1941) entitled “An Act to Expedite the

Prosecution of the War Effort” and Presidential Executive Order No.

9001 (December 27, 1941). It furthermore stated that “the contractor

will assemble and load complete rounds of 40 mm ammunition.”

This contract was preceded by a Letter of Intent dated March 4,

1942, between the Government and the contractor to expedite the

completion of the facilities in the interest of the successful

prosecution of the war. The properties began to be purchased and

assembled in June, 1942, and the plant was operational by November of

that year. The contract consists of 24 pages with 33 Articles and an

Appendix.

Can you imagine how long it would take to follow

that process in 2015? From the intent to purchase, to contracts with

the land owners, to a time for inspection, rezoning applications,

public hearings, building permits and approvals, construction

contracts, and completion would take years in today’s marketplace.

Yet in 1942, the acquisition and construction was accomplished in

less than six months.

The following article is reprinted from Volume 1, Building the

Navy’s Bases in World War II: History of the Bureau of Yards and

Docks and the Civil Engineer Corps, 1940-1946, by the United States

Government Printing Office, Washington, 1947.

On the first

of June 1942, a contract was made by the Navy department with the

United States Rubber Company, for the construction of a 40-mm shell

loading and assembly plant on a 2,260 acre site, 10 miles south of

Charleston, N. C.

In this construction, 249 individual

buildings, ranging in size from 6 by 6 feet to 870 by 500 feet, were

erected, most of them of wood-frame construction concrete-block

foundations. The plant had three loading lines, and construction was

planned so that the first of these was completed and in operation

while work continued on the other two. Within the area, 13 miles of

railroad tracks and more than 8 miles of gravel roads were

constructed. Wide dispersal of the plant made a central heating

system impracticable, and five boiler houses were erected so that

each could serve one or two general areas. A complete sewerage and

sewage-disposal system for the plant was installed. Water was

obtained from the city of Charlotte.

The first test shells

were loaded on December 12, 1942, and loading line No. 1 was in

operation by December 17.

Other plants for loading 40-mm and

20-mm shells were constructed at Bristol, Va., Mayfield, Ky.,

Chillicothe, Ohio, Elkton, Md., Peru, Ind., and Hanover, Mass. Each

plant included many buildings dispersed over a wide area.

|

Yes, the first paragraph said it was “south of Charleston,

NC.” They got the city right in the second paragraph about the water

supply.

Not everyone was happy with the decision to locate the plant in

Steele Creek and Pineville Townships. The following is a portion of

an unpublished article by Linda Blackwelder. The newspaper article

referred to is from the Charlotte Observer, November 22, 1942,

written by Marion Wright.

The U. S. Rubber Company hurried

construction of the 2,400 acres to manufacture ammunition for the

war effort. The community was stunned. In an article in the

Charlotte Observer in the fall of 1942, it was noted that this was

some of the best farm land in the area and that, “Home-loving,

God-fearing men and women have tilled this soil since before the

American Revolution. They erected homes, established churches and

schools. A progressive, albeit a quiet and pleasant community, had

evolved through each succeeding generation until today. Its success

is not measured as much by material well-being as by its deep

rooted feeling of permanency and law abiding citizenship; its

idealism centered in home, church and community development.” The

community asked the Rev. Dr., Raymond Young, minister of Central

Steele Creek Presbyterian and Pleasant Hill Presbyterian, to act as

spokesman for them and after appealing to the Charlotte Chamber of

Commerce and then to Congressmen, the protest was sent to the

Secretary of the Navy. The Secretary explained in his reply that

this site was chosen, “because of level terrain, an interior

location, easy transportation facilities and the type of pure labor

needed, already at hand. Sorry I cannot grant the request and hope

for the community co-operation.”

The community already had

sent their sons to war and knowing the need for this facility to

help the war effort, Dr. Young aided the community in no further

protest. He stated, “Resentment died a natural death and full

co-operation has been accorded from that day on, in every way

possible. Men and women of the community joined the force of workers

at the plant and all available space in the homes for miles around

is filled with workers from supervisors to laborers. The plant is

nearing completion now and we still hold on to our cherished ideals

and make every effort to keep them alive.” At that time, Dr. Young

made the statement that the facility would change Steele Creek

community forever. At the time he said it, few would have any idea

just how much the statement was true.

Central Steele Creek

Presbyterian on York Road (now South Tryon Street) sat just yards

from the entrance to this guarded facility and did all they could to

help entertain, feed, and provide spiritual enrichment to those who

worked at the facility. |

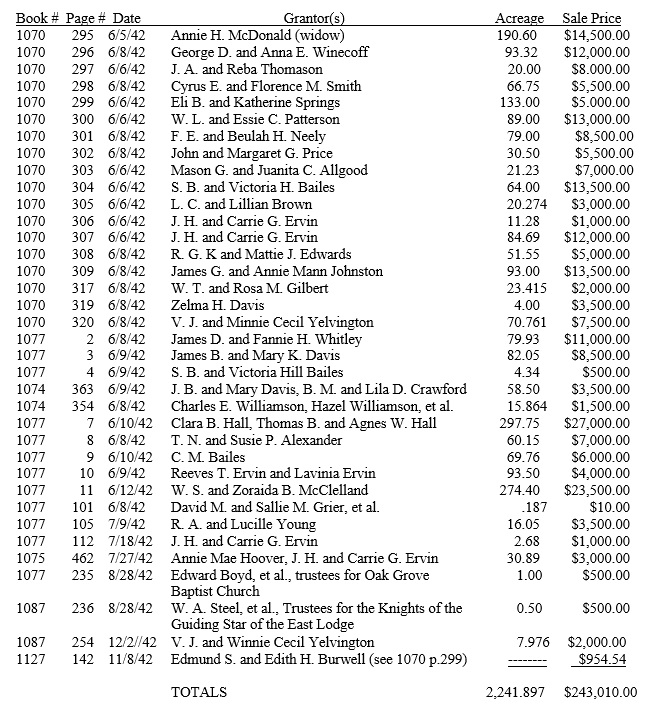

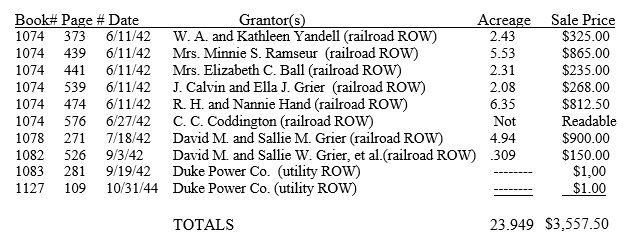

So, how did they manage to assemble such a large parcel of land in

such a short time? The Register of Deeds of Mecklenburg Count

records the sales of the property to United States Rubber Company, a

New Jersey Corporation with an office at Rockefeller Center, 1230

Sixth Avenue, New York, N.Y.

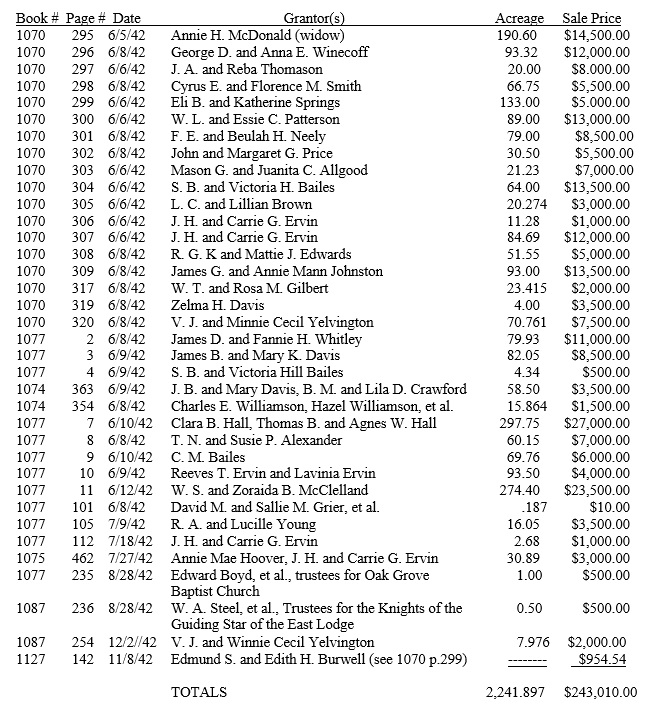

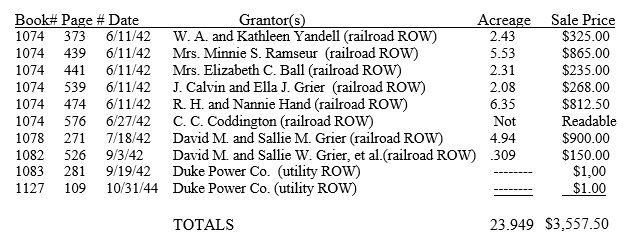

In addition, United States Rubber Company purchased Right of Way for

utilities and railroad from the following:

The average sale price was a little over

$108.00 per acre. However, the lowest sale price was $42.78 per acre

and the highest was $875.00 per acre. It is unclear if agents of the

purchaser contacted the property owners as a group or approached

each individually. Was it done quietly or publically?

Part 2 of the Shell Plant history covers

plant operations during the war. See

Steele Creek Contributed to the World War II Effort.

Walter would like

to interview anyone who has information about those who worked at

the plant or sold land for the plant. Please contact Walter Neely by email

at wlewneemoo@aol.com if you worked at the Shell

Plant or sold property or know anyone who did and can contribute to

the story. He will try to contact you to get a

personal interview.

To comment on this

story, please visit the

Steele Creek Forum.

Click here:

to share this story to your Facebook page,

or click below to visit the Steele Creek Residents Association

Facebook page.

to share this story to your Facebook page,

or click below to visit the Steele Creek Residents Association

Facebook page.

. .

|